This is the latest iteration of my printer build. Essentially, I’ve added 5 colour capability by using a Diamond 5 colour hot end. To do this, I needed to add 2 extra extruders which added a significant amount of weight. Previously, the extruders were mounted on their own gantry which was passively “dragged around” by the hot end. Although this would seem to be a bad idea, it actually worked surprisingly well. However, the extra two extruders plus my desire to mount them on dual rails, rather than a single rail, meant that the total mass that needed to be moved in the Y direction increased from around 2,800 gms to about 4,000 gms and the mass of the extruder gantry assembly is now significantly greater than the mass of the hot end assembly. So, I decided that it was time to actively drive the extruder gantry, rather than rely on the hot end to “drag it around”.

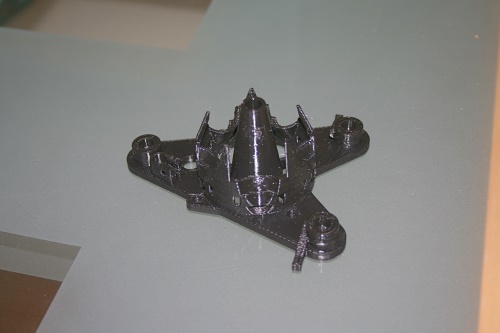

The first thing I had to do was to design a mount to take the 5 colour nozzle. Here it is,

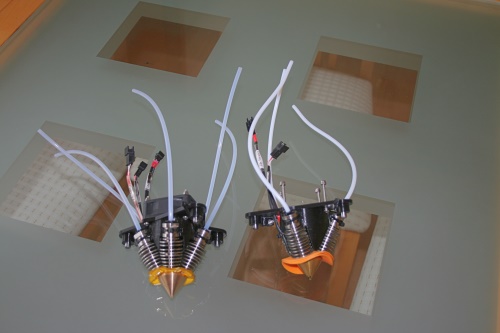

It uses the same locating mechanism as the 3 colour version so I can swap between 3 colour with 0.5mm nozzle, 3 colour with 0.9mm nozzle and 5 colour with 0.5mm nozzle. Here is the new 5 colour assemble next to the 3 colour version.

The next thing to do was design a new gantry for the extruders. I decided to make it a mirror of the lower gantry with the exception that the rails needed to be longer because the extruder assembly is wide than the hot end. Here are the printed parts.

And this is the complete gantry.

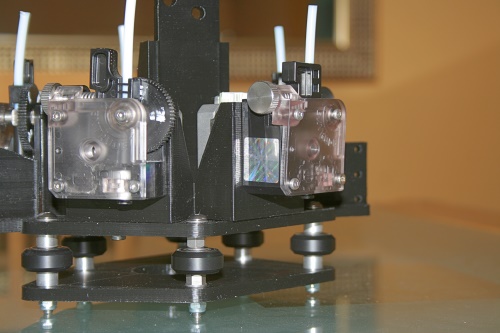

This is what 5 E3D Titans look like mounted on their carriage

……….and from the side

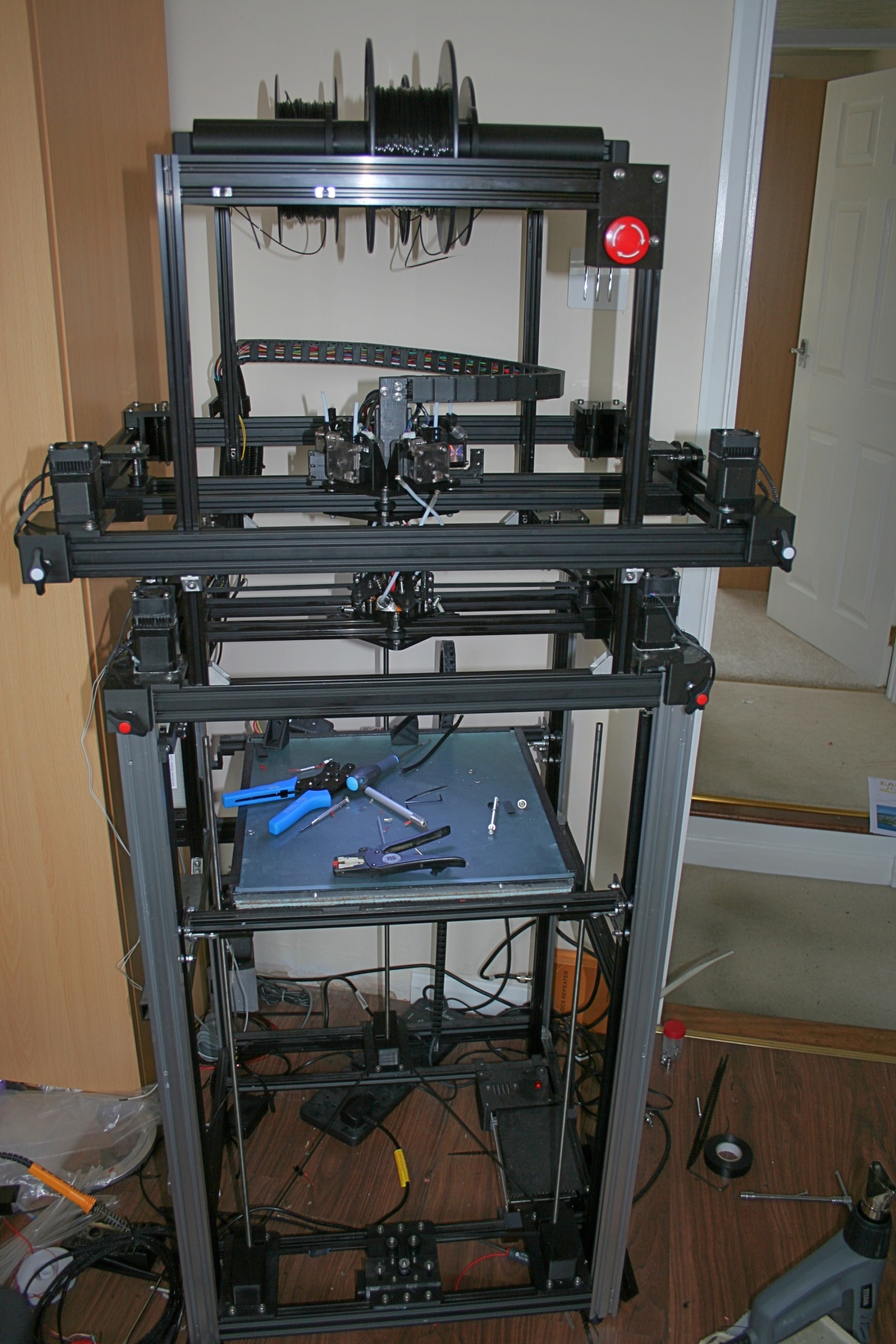

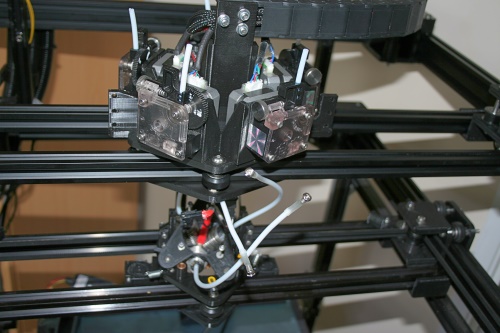

This is the entire assembly mounted on the frame

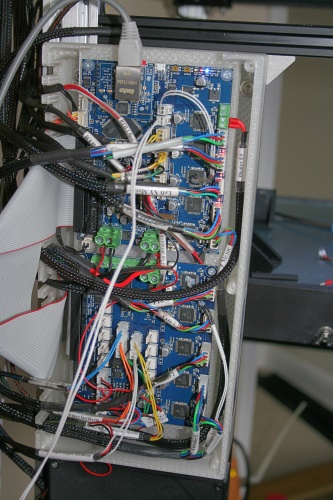

Of course, I also had to do a fair bit of wiring to accommodate the two extra XY motors as well as the two extra extruder motors. I also fitted cooling fans to the XY motors which run in thermostatic mode to prevent the plastic motor mounts from distorting.

So the extruder gantry is an entire Core XY mechanism, driven by it’s own motors. The motors are mapped such that “X” uses drives 0 and 3, “Y” uses drives 1 and 4, Z uses drive 2 and the extruders are driven by drives 5 to 9 on the Duex5 board. This means that the all the stepper drivers on both the Duet and the Duex 5 are now fully utilised.

Finally, this is how it looked at the end..

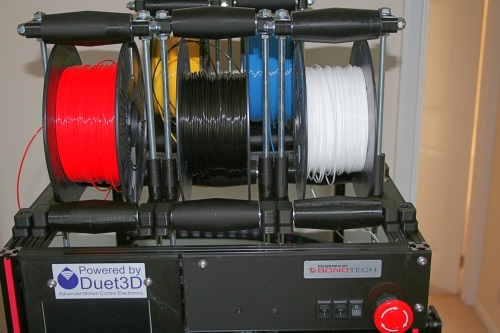

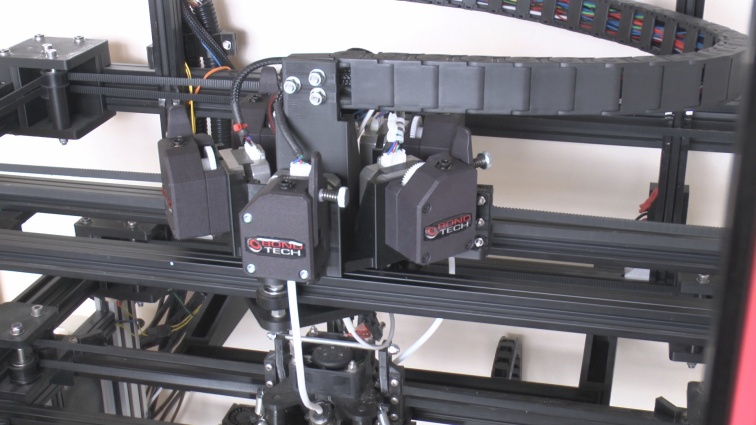

As of June 2018, the extruders have been changed to Bondtech BMGs……

….. and the filament holder has been changed to a version which is tangle free and makes changing reels much easier.